How do I start 3D printing?

Understanding the Basics of 3D Printing

3D printing technology has revolutionized the world of manufacturing, enabling anyone with a 3D printer to create complex and intricate objects at home. But how does 3D printing work, and what are its basic principles?

At its core, 3D printing is an additive manufacturing process that builds three-dimensional objects layer by layer from a digital model. The process typically begins with designing or obtaining a 3D model, which is then transferred to the printer's software. The software slices the model into thin cross-sectional layers, which are then printed one on top of the other until the object is complete.

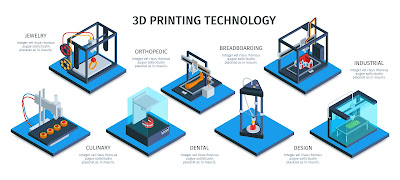

There are several types of 3D printers available, each using a slightly different methods and materials. The most common is Fused Deposition Modeling (FDM), which melts and extrudes a thermoplastic material through a nozzle to create the object layer by layer.

Other types of 3D printers include Stereolithography (SLA), which uses a UV laser to cure liquid resin into solid layers, and Selective Laser Sintering (SLS), which creates the thing by fusing powdered material together with a laser.

The choice of printing material can greatly affect the outcome of your 3D prints. Common materials used in 3D printing include PLA, ABS, PETG, and nylon, each with their own unique properties and strengths.

With a basic understanding of how 3D printing works and the types of printers available, you can start exploring the limitless possibilities of this exciting technology.

Selecting the perfect 3D Printer for your Needs

With so many options available, it can be overwhelming to choose the right 3D printer. The key to selecting the perfect printer for your needs is to consider your budget, desired features, and printing requirements. Here are some tips for choosing a 3D printer:

- Determine your budget: 3D printers can range from a few hundred to several thousand dollars. Decide on a budget that works for you and narrow down your options accordingly.

- Consider your printing needs: Are you printing small objects or large ones? Do you need high precision or is a lower resolution sufficient? These factors will help determine the type of printer you should select.

- Choose a reputable brand: Look for established brands with positive reviews and good customer support. A well-known brand can give you peace of mind when making your purchase.

- Research different models: Read reviews and compare the features of different models to find the one that best fits your needs. Look for printers with user-friendly interfaces and easy-to-use software.

- Consider the materials: Some printers are compatible with only specific types of filament, while others can print with a wider variety. Make sure the printer you choose can use the materials you want to print with.

The best 3D printers for beginners are typically those with a lower price point, easy-to-use software, and simple calibration processes. Some popular models include the Creality Ender 3, Monoprice Select Mini, and Anycubic Photon.

Step-by-Step Guide to Setting Up Your 3D Printer

So, you've got your brand new 3D printer, and you're eager to start printing your first object. However, before you do that, you need to set up your printer. Here is a step-by-step guide to assembling and calibrating your 3D printer for optimal performance.

Step 1: Unboxing and Preparation

Take your 3D printer out of the box and ensure that all the components are present, including the power supply, filament, and necessary tools. Read the manufacturer's instructions carefully, and follow each step to ensure that everything is set up correctly.

Step 2: Assembly

Begin assembling your printer by following the manufacturer's instructions carefully. Attach the base plate to the frame, install the motors, and attach the extruder to the hot end. Verify that everything is correctly tightened and secured.

Tip: Keep all your 3D printer parts organized as you assemble to avoid losing any vital components.

Step 3: Printer Calibration

Once you've assembled your printer, it's time to calibrate it for optimal performance. This is a crucial step that ensures the accuracy and reliability of your prints.

- Level the bed: Ensure that your printer's bed is level by adjusting the bed leveling screws located under the bed. Use a sheet of paper to feel the nozzle's height, and adjust the screws until the nozzle is the right distance from the bed.

- Calibrate the extruder: Calibrate the extruder by ensuring that the filament is flowing correctly and consistently through the hot end.

- Adjust print settings: Adjust the print settings to optimize print quality. This includes setting the correct temperature for the hot end and bed, adjusting the print speed, and choosing the correct layer height and filament type for your print.

Selecting and preparing 3D models for printing

Before you can 3D print an object, you need a digital model of it. There are several ways to obtain 3D models, including downloading pre-made models from online repositories, using 3D scanning technology to create a model from a physical object, or creating your own model using Computer-Aided Design (CAD) software.

If you're new to 3D modeling, there are many beginner-friendly options available. Tinkercad is a free, browser-based CAD software that allows you to easily create and modify basic 3D models. Fusion 360 and SketchUp are also popular options for more advanced modeling.

Once you have a model, it's important to prepare it for successful printing. This includes ensuring the model is in the correct file format (usually STL or OBJ), checking for any errors or issues that could cause problems during printing, and orienting the model in a way that will allow for optimal printing. Many slicing software programs, which we'll cover in the next section, also include tools for preparing and optimizing models for printing.

Choosing printable models

When selecting models to print, it's important to choose ones that are suitable for 3D printing. Some models may have intricate details or overhangs that could be difficult to print without support structures, while others may require specific printing materials or settings. Look for models that are labeled as "3D printable" or have been tested by other users for successful printing.

Exploring the software used in 3D printing

3D printing requires specialized software to process and prepare your models for printing. In this section, we will introduce you to the various software options available, including slicer software and Computer-Aided Design (CAD) software.

3D printing software

3D printing software is used to convert a 3D model into instructions that a 3D printer can understand. This software takes the digital model and slices it into layers that can be printed one at a time. Some popular 3D printing software options include:

- Cura - an open-source slicing software that is compatible with most 3D printers

- Simplify3D - a commercial software that offers advanced features and high-quality prints

- PrusaSlicer - an open-source slicer developed by the 3D printer manufacturer, Prusa

Slicer software

Slicer software is specifically designed to slice the 3D model into printable layers. It allows users to adjust various printing settings such as print speed, layer height, and infill density. Some popular slicer software options include:

- Ultimaker Cura - an open-source slicing software that is user-friendly and offers a range of advanced features

- Slic3r - a free, open-source slicing software that is highly customizable

- IceSL - a free, open-source slicer that offers real-time slicing and previewing

CAD software

CAD software is used to create and modify 3D models. It is commonly used in architecture, engineering, and product design. Some popular CAD software options include:

- Fusion 360 - a cloud-based CAD software that offers both free and paid plans

- Tinkercad - a free, browser-based CAD software that is popular among beginners

- SolidWorks - a commercial CAD software that is widely used in product design and engineering

Choosing the right software for your 3D printing needs depends on your level of experience, desired features, and printing requirements. Consider trying out a few different options to find the one that works best for you.

An Overview of 3D Printing Materials

3D printing materials come in a variety of types, each with its unique properties and ideal uses. Choosing the right material can greatly affect the quality and durability of your prints.

- Filament Types: The most common 3D printing material is thermoplastic filament. This type of filament comes in several varieties, including PLA, ABS, PET, Nylon, and TPU. PLA is the most widely used filament for beginners due to its ease of use, low cost, and eco-friendliness. ABS is a tougher material that can withstand higher temperatures, making it suitable for functional prints. PET is a popular choice for 3D printing containers, while Nylon is known for its durability and strength. TPU is a flexible material used for creating objects with a rubber-like texture.

- Material Properties: Each filament type has its own unique properties that affect the print's appearance, strength, and flexibility. For example, PLA is a biodegradable and easy-to-print material, but it's prone to brittleness and warping. ABS is a strong and durable material that can handle higher temperatures but is more challenging to print and emits fumes, requiring ventilation. Nylon is a heat-resistant material that's durable and flexible, but it's also more challenging to print and requires a higher printing temperature.

When selecting a filament type, consider the desired outcome of your print and the properties required for its function. It's also essential to follow the manufacturer's guidelines for printing with a specific filament type to achieve optimal results.

Tips for improving print quality

3D printing can be a rewarding experience, but achieving high-quality prints may require some fine-tuning. Here are some tips to improve your print quality:

Optimize your print settings

Adjusting your print settings can have a huge impact on the quality of your prints. Experiment with print speeds, layer heights, and temperature settings to find what works best for your printer and the material you're using. Remember to make small adjustments at a time and keep track of your changes.

Level your build plate

An uneven build plate can cause issues such as warping, adhesion problems, and print failures. Make sure your build plate is level before each print. Most printers come with a built-in leveling feature, but you can also use a piece of paper to check the distance between the nozzle and the build plate at each corner of the bed.

Use quality filament

Not all filaments are created equal, and using a low-quality or expired filament can negatively impact your prints. Invest in high-quality filaments from reputable manufacturers and store them properly to avoid moisture absorption and other environmental factors that can affect their properties.

Check your printer's components

Regularly inspect your printer's components, such as the nozzle, extruder, and belts, to ensure they are clean and functioning properly. Clogs, wear and tear, and other issues with these components can lead to poor print quality or failed prints.

Troubleshoot issues

Even with the best settings and materials, issues can still arise during printing. Learn how to troubleshoot common problems such as layer shifting, under extrusion, and over extrusion. Solutions can include adjusting settings, cleaning components, or replacing parts.

By following these tips and staying patient, you can greatly improve your 3D print quality and achieve the results you desire.

Enhancing and Finishing Your 3D Prints

Once your 3D prints are complete, it's time to enhance their appearance and functionality. Here are some post-processing techniques you can use to take your 3D prints to the next level:

Sanding

Sanding is a common technique used to smooth the surface of 3D prints. It can help remove any imperfections and create a smoother finish. Use a fine-grit sandpaper and gently rub it over the surface of your print in a circular motion.

Painting

Painting your 3D prints can add color and personality to your designs. Use spray paint or acrylics to paint your prints, but make sure to apply a primer first to create a smooth surface.

Adding Finishing Touches

There are many ways to add finishing touches to your 3D prints. For example, you can add a clear coat to protect the surface, apply decals or stickers, or even use special effects like metallic paint or glow-in-the-dark filament.

By using these post-processing techniques, you can transform your 3D prints into polished, professional-looking objects that are sure to impress.

Ensuring Safety While 3D Printing

While 3D printing can be a fun and exciting hobby, it's important to prioritize safety to protect yourself and those around you. Follow these safe printing practices:

- Always read the manufacturer's instructions and warnings before operating your 3D printer.

- Do not touch the printer's nozzle or build plate while it's printing, as they can reach high temperatures.

- Keep your 3D printer in a well-ventilated area to avoid inhaling fumes from melting printing materials.

- Wear protective gloves and a mask when handling printing materials, especially if they are chemicals or toxic substances.

- Store your printing materials and chemicals in a safe, secure location away from children and pets.

- Regularly inspect your 3D printer for any signs of wear and tear, and perform necessary maintenance or repairs.

- Do not leave your 3D printer unattended while it's printing, and always have a fire extinguisher nearby in case of emergencies.

By following these safety tips and handling printing materials responsibly, you can enjoy 3D printing with peace of mind.

Conclusion

Starting your 3D printing journey can seem overwhelming, but with the knowledge and resources provided in this guide, you're well-equipped to begin. With a thorough understanding of the basics of 3D printing, you can confidently select the perfect printer for your needs and set it up for success.

By following our step-by-step guide, you can create high-quality prints and enhance their appearance and functionality with post-processing techniques. It's important to always prioritize safety, ensuring a safe printing environment by handling printing materials correctly and maintaining your printer's safety features.

With your creativity unlocked and your ideas brought to life, you're on your way to becoming a skilled 3D printing enthusiast. So what are you waiting for? Start your 3D printing journey today!

FAQ

What is 3D printing technology?

3D printing, also known as additive manufacturing, is a technology that creates three-dimensional objects by layering materials on top of each other based on a digital model.

How does 3D printing work?

3D printing works by slicing a digital model into thin layers and then using a 3D printer to sequentially deposit or fuse material layer by layer until the object is complete.

What are the different types of 3D printers available?

There are various types of 3D printers, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP), among others.

What materials are commonly used in 3D printing?

Common materials used in 3D printing include plastic filaments such as PLA and ABS, resin for SLA and DLP printers, metal powders for metal 3D printing, and even concrete for large-scale construction projects.

How do I choose the right 3D printer for my needs?

When selecting a 3D printer, consider factors such as your budget, desired features (e.g., print size, resolution), your level of expertise, and the type of objects you plan to print.

How do I set up my 3D printer?

Setting up a 3D printer involves assembling the machine, calibrating it for optimal performance, and ensuring that the necessary software is installed and correctly configured.

How do I obtain or create 3D models for printing?

3D models can be obtained from online repositories, created using 3D modeling software, or scanned using a 3D scanner. It's important to prepare the models for successful 3D printing by ensuring they are manifold and error-free.

What software is used in 3D printing?

3D printing software includes slicer software, which prepares the digital model for printing by generating the toolpaths, and Computer-Aided Design (CAD) software, which allows for the creation and modification of 3D models.

What are some tips for improving print quality?

To improve print quality, consider fine-tuning print settings such as layer height, temperature, and print speed. Additionally, ensure proper bed adhesion, use support structures when necessary, and monitor for common issues like stringing or warping.

How can I enhance the appearance of my 3D prints?

Post-processing techniques such as sanding, painting, and adding finishes can enhance the appearance and functionality of 3D prints. These techniques help smooth surfaces, add color or texture, and provide a professional finish.

What safety precautions should I take while 3D printing?

Safety precautions include carefully handling printing materials, ensuring proper ventilation when using certain materials, and being mindful of the printer's hot components. It's also important to follow manufacturer guidelines and maintain safety features.

Thank you

ReplyDeletewelcome dear

Delete